High-Strength Worsted Yarns: Reshaping the Performance Benchmark in the Textile Industry

2025.08.22

2025.08.22

Industry News

Industry News

Throughout the textile industry's long evolution, yarn, as a fundamental raw material, has consistently driven industry upgrades through performance innovation. High-Strength Worsted Yarns, with their superior mechanical properties and exquisite texture, are gradually moving from the professional realm to the mainstream, becoming a new favorite in the high-end textile market. This specially processed yarn not only breaks the traditional "strength and feel" dilemma, but also demonstrates the potential to rewrite industry standards in a variety of applications.

Precision Forging Through Combing: A Double Breakthrough in Strength and Texture

The unique appeal of high-strength combed yarn stems primarily from its exquisite craftsmanship. The combing process, a key step differentiating it from carding, involves mechanically removing short fibers, impurities, and hooked fibers from the fibers, leaving the remaining long fibers aligned more evenly and straightly. This seemingly simple process actually places stringent demands on equipment precision and process parameters. The speed of the combing rollers, the control of fiber grip, and even subtle changes in ambient temperature and humidity can directly impact the final yarn's performance.

Combed fibers achieve more uniform stretching and twisting during the spinning process, resulting in a yarn with a denser structure and stronger interfiber cohesion. This optimized internal structure distributes stress more evenly across each fiber when subjected to external forces, preventing breakage caused by excessive localized stress. Furthermore, the removal of short fibers creates a smoother yarn surface, reducing pilling and imparting a delicate, smooth feel, achieving a perfect balance of strength and texture.

Raw Material Innovation: From Natural to Synthetic: A Superposition of Performance

The breakthrough performance of high-strength combed yarns is inseparable from innovative raw material selection. Traditional combed yarns are primarily made from natural fibers such as cotton and wool, and have established a niche market thanks to the excellent properties of these natural fibers. Modern high-strength combed yarns build on this foundation by incorporating blending techniques with a variety of high-performance fibers, creating a more diverse raw material system.

Among natural fibers, long-staple cotton, due to its slender fiber structure, is an ideal choice for enhancing yarn strength. Combing enhances the bonds between long-staple cotton fibers, resulting in yarns that not only offer exceptional strength but also retain cotton's inherent breathability and moisture absorption properties. Wool fibers undergo a refinement process, enhancing the yarn's tensile strength while maintaining elasticity, making it particularly suitable for high-end thermal fabrics.

The addition of chemical fibers further expands the performance boundaries of high-strength combed yarns. Synthetic fibers such as polyester and nylon possess inherent strength, and when blended with natural fibers, they significantly enhance yarn durability without sacrificing comfort. The use of new functional fibers such as carbon fibers and aramid fibers has enabled high-strength combed yarns to enter the industrial market, providing a solid raw material foundation for specialty textiles.

Multi-dimensional Performance Advantages: Beyond the Traditional User Experience

The performance advantages of high-strength combed yarns are reflected in multiple dimensions of excellence. Its core high-strength properties make the fabric more resistant to wear and tear during daily use, significantly extending the product's lifespan. This advantage is particularly evident for textile products subjected to frequent stress, such as workwear and sportswear, effectively resisting the wear and tear caused by long-term use.

In addition to its strength, high-strength combed yarns also possess excellent dimensional stability. Fabrics made from these yarns resist deformation and shrinkage after washing and drying, maintaining their excellent appearance over time. This feature not only enhances the product's practicality but also provides greater flexibility in garment pattern design.

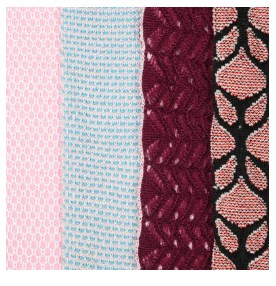

The combing process imparts a uniform yarn structure, resulting in a smoother, more evenly saturated fabric surface and richer, more uniform color. During the printing and dyeing process, the fibers absorb dye more consistently, reducing color variations and color fringing, resulting in a fabric with higher visual quality. This aesthetic advantage has made high-strength combed yarns highly sought after in high-end apparel, home textiles, and other sectors.

Widely Expanding Applications: Cross-Border Penetration from Apparel to Industrial Applications

The application of high-strength combed yarn is expanding with its improved performance, extending from traditional apparel to industrial textiles. In the apparel industry, high-end menswear and functional outdoor apparel are key areas of focus. Suiting fabrics made with high-strength combed yarn are crisp, wrinkle-resistant, and maintain their long-lasting aesthetic. Outdoor apparel, on the other hand, leverages its high strength and weather resistance to provide reliable protection.

High-strength combed yarn also holds a significant position in the home textile sector. High-end bedding, curtains, and other products made with this yarn not only offer a delicate and comfortable feel but also resist the friction and wear of daily use, maintaining a long-lasting, pristine appearance. Particularly in the high-end home furnishing market, this yarn, combining both quality and durability, is a key factor in enhancing product value.

In industrial textiles, the potential for high-strength combed yarn is being gradually realized. In the transportation sector, automotive interior fabrics made with this type of yarn are able to withstand long-term friction and high temperatures, extending their service life. Protective textiles in the construction sector, such as safety nets and waterproof fabrics, also benefit from the yarn's high strength, enhancing safety. In specialized fields like healthcare and aerospace, specialty textiles made from high-strength combed yarns are playing an irreplaceable role thanks to their unique properties.

The rise of high-strength combed yarns reflects not only advancements in textile technology but also the market's growing demand for high-quality, high-performance textiles. From sophisticated craftsmanship to innovative, diverse raw materials, from superior performance to a wide range of applications, this new type of yarn is reshaping the textile industry with its unique advantages. Driven by both green and intelligent technologies, high-strength combed yarns are poised to flourish in even more sectors, injecting continuous momentum into the high-quality development of the textile industry.