High-grade Wool Fancy Yarns: A Leading Force in Textile Aesthetics and Functionality Innovation

2025.08.01

2025.08.01

Industry News

Industry News

Amidst the current textile market's constant pursuit of differentiation, functionality, and fashion, high-grade wool fancy yarns are becoming a significant innovative force within the wool textile industry chain. These yarns not only retain the natural advantages of traditional wool fibers, but also, through breakthroughs in structural design and processing, offer a unique appeal in terms of fabric aesthetics, tactile performance, functionality, and applicable applications. With consumption upgrades and the market's growing demand for high-value-added textiles, high-grade wool fancy yarns are at the forefront of a new textile material revolution.

A fusion of nature and art: The material foundation of high-end wool fancy yarns

The core advantage of high-grade wool fancy yarns stems from the scarcity and superiority of their natural raw materials. High-quality raw wools, such as Australian Merino and Tasmanian wool, are selected to ensure their natural crimp, warmth, and skin-friendly properties. This raw material base not only imparts a smooth and delicate feel and excellent thermal and moisture-regulating properties to the yarn itself, but also provides a broader technical space for subsequent fancy structure design.

High-end fancy wool yarns often utilize a composite raw material combination strategy. By blending with mohair, alpaca, mulberry silk, and silk protein fibers, these natural fibers complement each other's performance, providing the product with a higher level of comfort, gloss, and elasticity, further enhancing the overall yarn quality and market competitiveness.

Structural innovation is the key: Diverse fancy craftsmanship delivers both visual and tactile value.

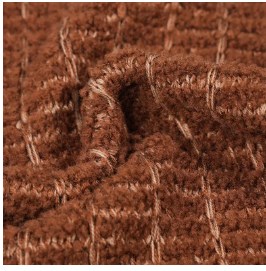

Compared to traditional wool yarns, the most recognizable feature of high-end fancy yarns is their asymmetrical and irregular surface structure. By utilizing multiple spinning techniques, such as ring spinning, open-end spinning, ring twisting, and core spinning, and supplemented by specialized fancy spinning machines for drafting, covering, looping, and knotting, the yarns are endowed with a highly three-dimensional visual and tactile quality.

For example, the unevenly coarse knots created by multiple twist variations can impart a natural, rustic, and vibrant texture to the fabric. Finishing techniques such as napping and spraying create a soft, three-dimensional velvety feel on the yarn surface, enhancing its warmth and artistic expression. This diverse range of structural processes enables high-end wool fancy yarns to meet the diverse needs of fashion brands for personalized and differentiated designs.

Combining Functionality and Aesthetics: The Performance Characteristics of High-end Wool Fancy Yarns

Functionally, high-grade wool fancy yarns not only excel in warmth, breathability, and moisture absorption, but also, through process adjustments, enhance pilling resistance, strength stability, and dimensional stability, meeting the stringent requirements of modern apparel fabrics for practicality and durability.

Driven by fast-paced consumer trends, more and more fabric developers are choosing yarn materials that combine aesthetics and functionality. High-end wool fancy yarns retain wool's warmth and comfort while imparting natural elasticity and wrinkle resistance through a modified yarn structure, making them an ideal material for high-end fall and winter fashion, knitted coats, scarves, shawls, and luxury knitwear.

At the same time, driven by the concept of sustainable development, some high-end wool fancy yarn manufacturers have begun to incorporate green eco-spinning concepts, using non-toxic, environmentally friendly additives, energy-saving, low-carbon processes, and achieving international environmental certification standards. This ensures that their products possess ecological value beyond aesthetics, providing solid support for brands' efforts to create "green fashion."

Market-Driven High-End Application Trends: Expanding Across the Scope from Fashion to Home Textiles

As consumer aesthetics and lifestyles evolve, the application of high-end wool fancy yarns has gradually expanded from their initial applications in luxury knitwear to include interior soft furnishings, functional accessories, and even high-end home textiles. Their unique artistic texture and comfortable feel make them a standout in sofa fabrics, cushion upholstery, and bedding, significantly enhancing the ambiance and sense of quality in any space.

Especially in the current rapidly developing customization market, brand clients are increasingly leveraging the differentiated visual language of fancy yarns to create limited-edition collections and high-end styles. This is driving the mainstream adoption of small-batch, multi-style, high-value-added textile supply models. This provides ample growth potential for high-end wool fancy yarns, while also placing higher demands on quality control and delivery capabilities for their manufacturers.

As people's pursuit of personalized, high-quality, and eco-friendly lifestyles continues to evolve, high-end wool fancy yarns, with their unique structural aesthetics and superior performance, are no longer simply a textile raw material, but a key carrier that integrates multiple values: fashion, function, art, and environmental protection. In the future, they will continue to lead the wool textile industry's differentiated competitive path and play an increasingly important role in the international high-end yarn market, building a new landscape for high-end textiles that combines the charm of traditional craftsmanship with the support of modern technology.